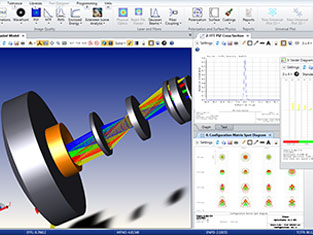

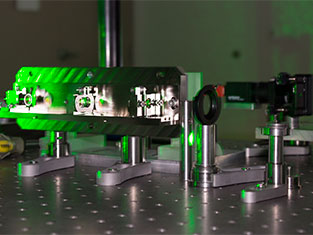

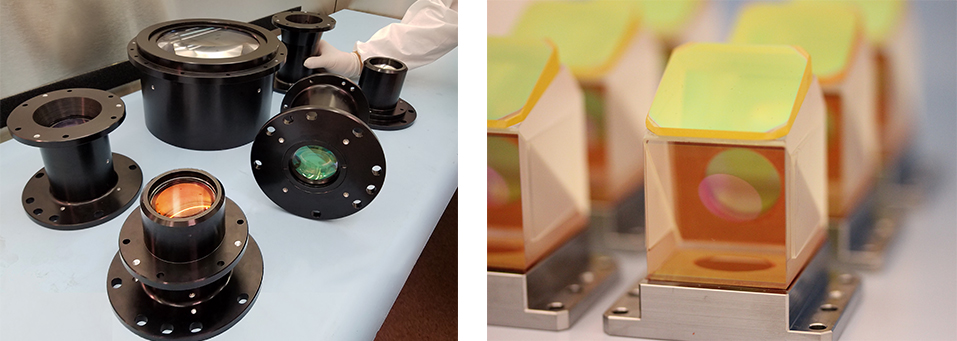

Complex Optical Assemblies If you need specialized optical engineering support, RMI is uniquely qualified to assist you. Our end-to-end opto-mech program incorporates state-of-the-art design services, vertically integrated manufacturing capabilities (including an in-house machine shop), and advanced testing and metrology. As a small company with large enterprise capabilities, we take pride in collaborating closely with our clients to deliver ideal opto-mechanical solutions quickly and affordably. Because we offer so many years of experience in prototyping and manufacturing, you can rest assured that you will receive leading-edge technology, unmatched engineering support and careful attention to your precise needs. Our complete in-house optical assembly program includes advanced capabilities in optics, coatings, diamond turning, machining, assembly and certification. We specialize in creating customized lens objectives, prism assemblies, optical transmitter and receiver assemblies, and advanced optical fixtures.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

By collaborating closely with our customers from the early stages of development,

RMI is able to meet the most challenging technical requirements to produce the highest

quality optics in prototype and production quantities.

RMI is able to meet the most challenging technical requirements to produce the highest

quality optics in prototype and production quantities.